Manual Penal bender(Bending center )

1、Main Configuration Instructions:

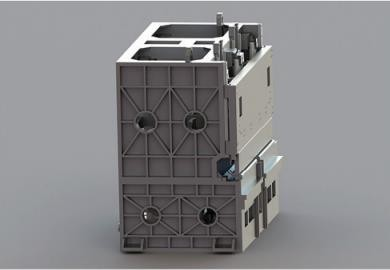

High-grade casting body

The core frame of the equipment is constructed from high-grade QT500-7 and gray iron 250 castings.

The entire machine is designed and manufactured according to high-precision machine tool standards. Both castings and welded components undergo rigorous stress relief treatment and are rigorously inspected using high-precision testing equipment to ensure long-term operational accuracy, stability, and high rigidity.

Heavy-duty screw

Taiwan MYE TBI heavy-duty ground-grade screw is used for more stable transmission and higher precision.

This design achieves the highest speed and precision and ensures extremely low operating costs.

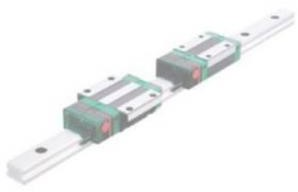

High-strength linear rails

Taiwan PMI/SHAC heavy-load high-precision roller linear guides are used, which have greater load-bearing capacity and higher precision.

2、Main technical parameters:

| KMB-2200 Technical Parameters | |

| Feeding structure | Arm Type |

| Workbench structure | Brush |

| Bending length | 2250mm |

| Sheet length | 2200mm |

| Sheet width | 1500mm |

| Bending height | 175mm |

| Minimum four-side forming dimensions | 320*200mm |

| Minimum two-side forming dimensions | 200mm |

| Minimum arc radius | 1.2mm |

| Maximum continuous bending speed | 0.5s/blade |

| Break distance between upper and lower blades | 190mm |

| Bending accuracy | 0.03mm |

| Bending angle | 0-180° |

| Maximum material thickness | Aluminum: 2.0mm / Carbon Steel: 1.5mm / Stainless Steel: 1.0mm |

| Minimum material thickness | 0.35mm |

| CNC system | SYNTEC/Taiwan New Generation |

| Operating system | Win7+OS |

| Number of axes | Standard 13 Axis |

| Rated voltage | 380V |

| Peak power | 24KW |

| Average power | 4.5KW |

| Machine dimensions | 4850mm*2780mm*2600mm |

| Machine weight | Approximately 12,000kg |

3、Configuration Details:

| KMB-2200 main functions and configurations | |

| Machine frame | Kefei independently designs and develops the frame, uses high-grade QT500 casting, and undergoes strict stress relief treatment to ensure the long-term operation accuracy, stability and high rigidity of the machine. |

| Mold | High-frequency quenching and tempering are adopted, which makes it more wear-resistant and has a longer service life. |

| Control system | Taiwan's new generation CNC system, independently developed by Kefei CNC, accurately achieves the perfect matching of all axes of the equipment in parallel, making program programming faster and easier. |

| Oil supply and self-lubrication system | The whole machine is automatically oiled and alarmed when oil is insufficient to ensure safe operation of the machine |

| Flattening function | Flattening of workpieces |

| Upper and lower edge pressing | Realize the upper and lower dead edge of the workpiece |

| Handwheel | The system has an anti-collision knife function, and the user can control each axis to any desired position through the handwheel |

| Automated production line interface | Can connect to upstream and downstream production equipment to achieve automated production |

| Advanced commands | Users can customize the design and control of complex workpieces according to their needs |

| Arc commands | Directly call the arc command and input the radius to achieve the arc bending |

|

Servo drive |

Inovance/Hechuan bus servo adopts advanced manufacturing technology, has strong overload resistance, is more suitable for quick start at the moment of bending, runs smoothly at low speed, and has high precision |

| Electrical components | Schneider of France, an internationally renowned electrical company, has more stable and reliable product performance |

| Micro relays | Japan Izumi relay, an internationally renowned brand, uses pure copper as the coil, which has excellent conductivity, stable power-on performance and long service life. |

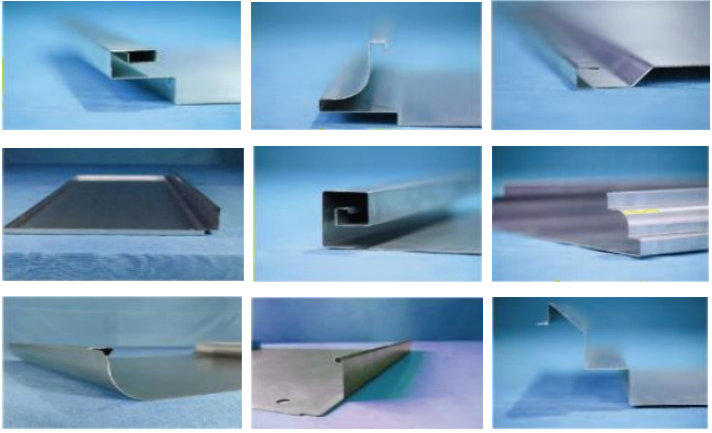

4、Bending case display

KaFe Panel Bender(Bending center) can bend sheet metal into various complex shapes without molds. It can bend right angles, non-right angles, arcs, up and down bends and other complex shapes, and is used in the metal forming field of different industries and different workpieces.

1) Display of actual folding workpieces

2) Application scenario display